The burgeoning Kingdom of Kennedy was in need of a mint so I stepped up and created a set of coins to present the noble leader of the fledgling nation as a Christmas gift.

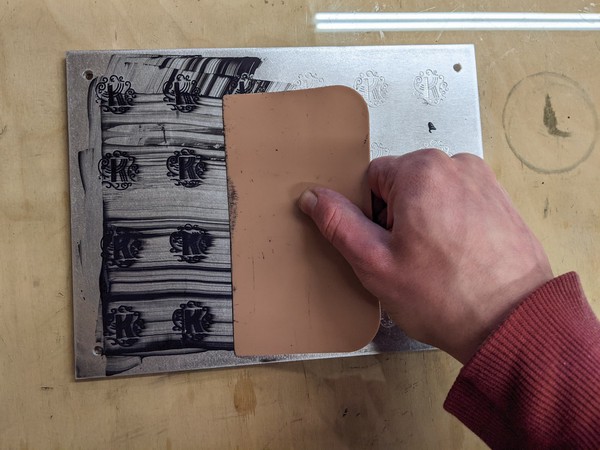

With an engraving process in mind, I set out to design for manufacturability. Details were synchronized with the size of the engraving tool. Accurately indexing both sides would be tricky so the design for the second side extended beyond the profile. This would provide a forgiving amount of tolerance when flipping the coins over for two-sided operations.

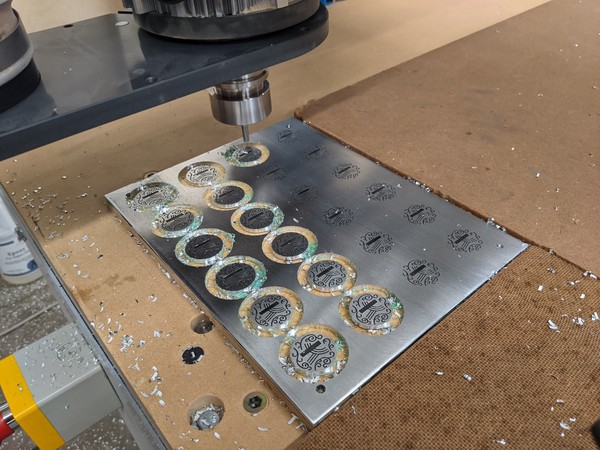

After a few back-and-fourths between engraving tests and design tweaks, it was time for a production run. Once a raw aluminum plate was lined up and the surface height accurately determined, the CNC machine got to work.

To make the engraved design visually pop, black enamel was applied. The excess enamel was removed from the flat surface but remained in the lower engraved details. The process reminded me of intaglio printmaking.

After sanding the surface to a fine level, I almost didn’t want to cut out the individual coins because the whole pattern was so striking together.

But the coins must be completed, so the individual profiles were routed into the plate, leaving small connecting tabs to prevent the individual pieces from violently dislodging. Then each coin was broken out by hand and the edges were cleaned up to take their final form.

A protective clear coat was applied to prevent oxidation and the coins were finished!

With the physical coins complete, one more element was needed yet to tie the set together: an official coin sleeve.